Ford Ecosport: Rear End Sheet Metal Repairs / Removal and Installation - Rear Floor Panel

Special Tool(s) / General Equipment

| Scraper for Straight Edges | |

| Spherical Cutter | |

| Hot Air Gun | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTE: To minimize the intrusiveness of the repair, the floor panel may be sectioned if desired. See floor panel sectioning in this section. The following assumes full component replacement. Adjust to meet repair needs.

NOTE: Rear doors, trunk panel, roof and parcel shelf removed for clarity.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

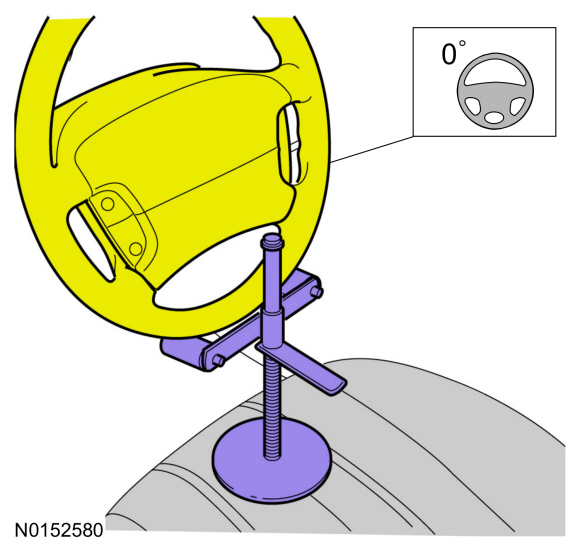

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If Required:

Dimensionally restore the vehicle to pre-damage condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the rear seat.

Refer to: Rear Seat Backrest (501-10B Rear Seats, Removal and Installation).

-

Remove the B, C and D-pillar trim panels.

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: C-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: D-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Remove the Loadspace Trim Panel.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Position the carpeting and the wiring harness away from the working area.

-

Remove the Back Panel and Reinforcement.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

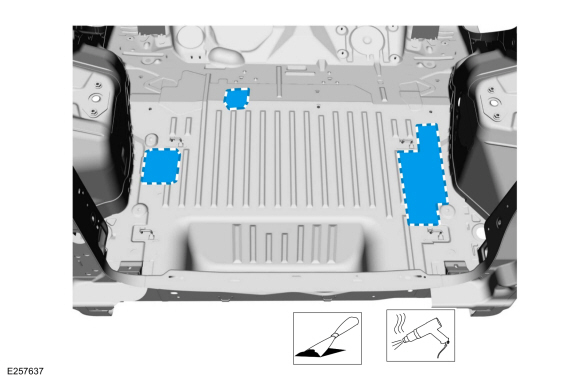

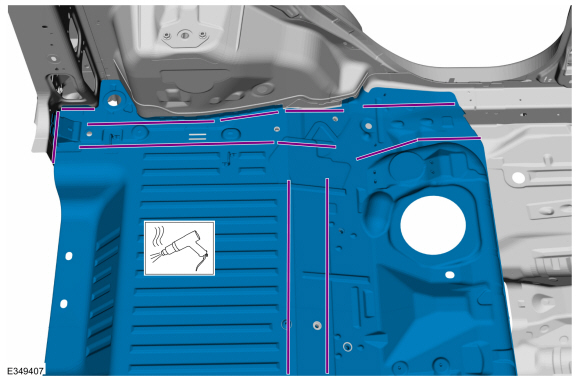

NOTE: Use of a heat gun may aid in removing the mastic material.

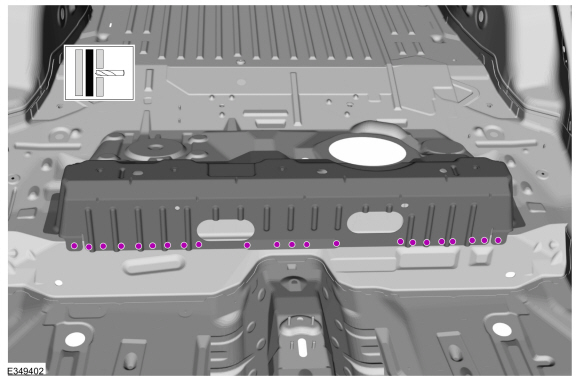

Remove the NVH mastic pads.

Use the General Equipment: Hot Air Gun

Use the General Equipment: Scraper for Straight Edges

|

-

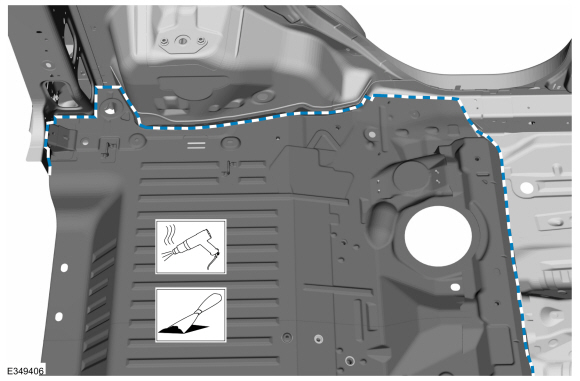

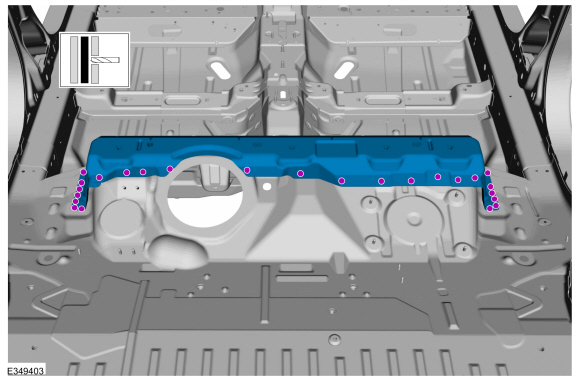

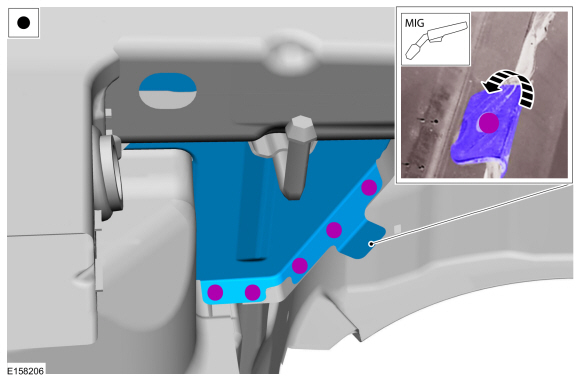

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

Remove the seam sealer.

Use the General Equipment: Hot Air Gun

Use the General Equipment: Scraper for Straight Edges

|

-

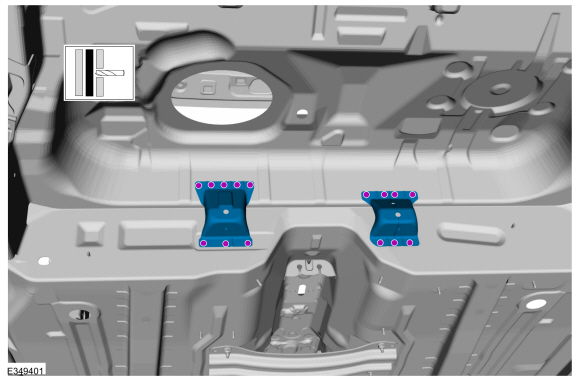

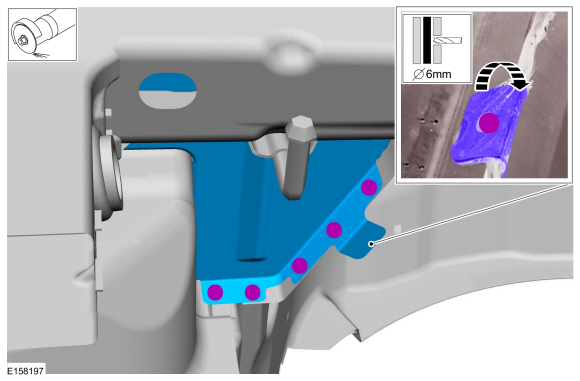

Remove the welds and fuel tank bracket.

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the welds and reinforcement.

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the welds and center floor panel.

Use the General Equipment: Spot Weld Drill Bit

|

-

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

Use the General Equipment: Spherical Cutter

|

-

NOTE: Pay particular attention to the location of noise, vibration and harshness (NVH) materials, adhesive and sealer to aid in installation.

NOTE: The use of heat may be required to soften adhesives and sealers.

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

On all side:

Remove the rear floor panel.

Use the General Equipment: Hot Air Gun

|

Installation

NOTE: Rear doors, trunk panel, roof and parcel shelf removed for clarity.

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

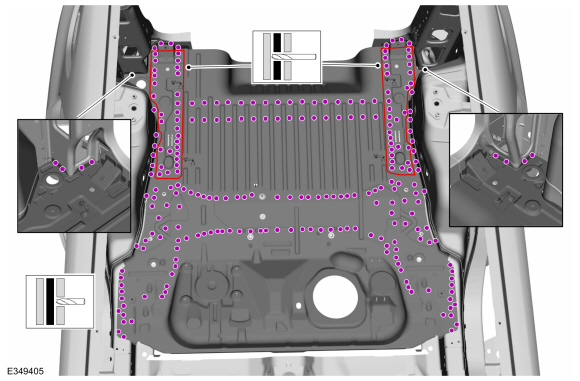

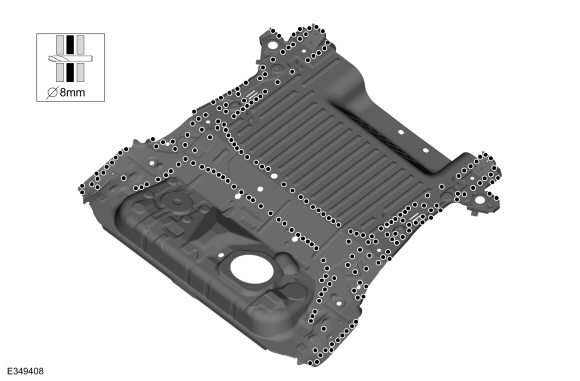

Drill plug weld holes in the replacement rear floor panel.

Use the General Equipment: 8 mm Drill Bit

|

-

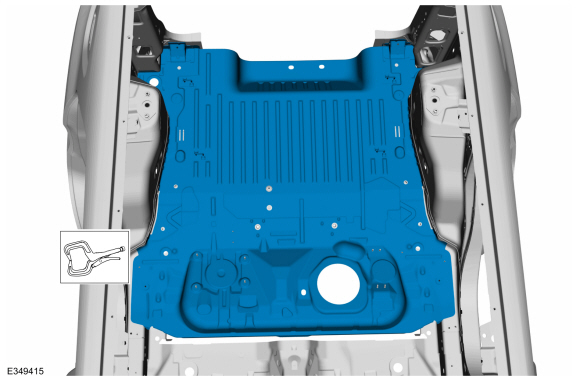

Install, properly position and clamp the rear floor panel.

Use the General Equipment: Locking Pliers

|

-

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

Install the welds.

Use the General Equipment: Spot Weld Drill Bit

Use the General Equipment: Spherical Cutter

|

-

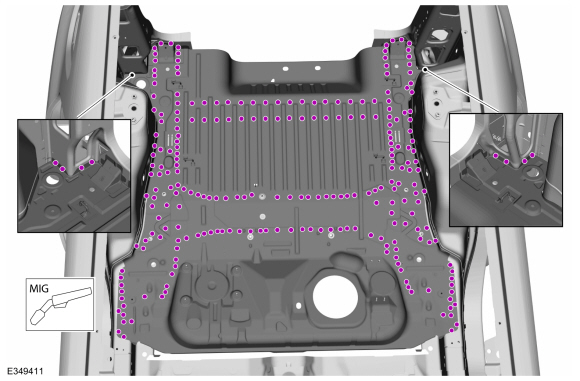

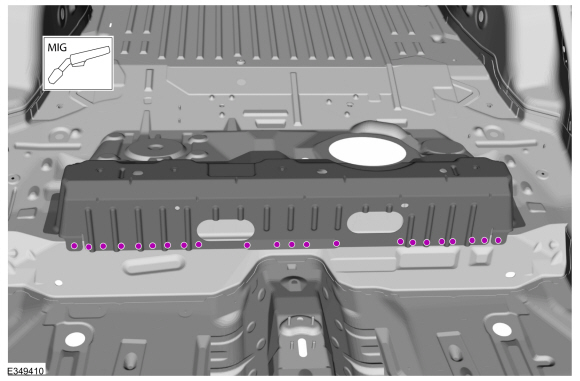

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

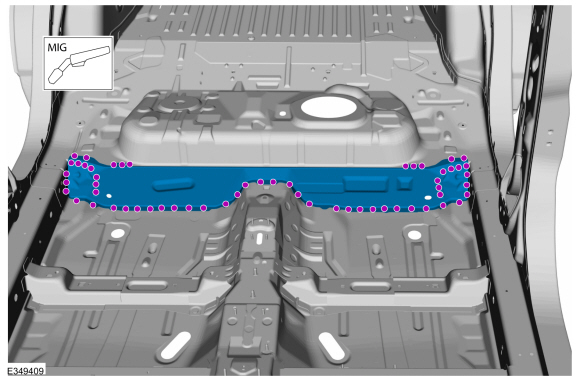

Install the welds and center floor panel.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

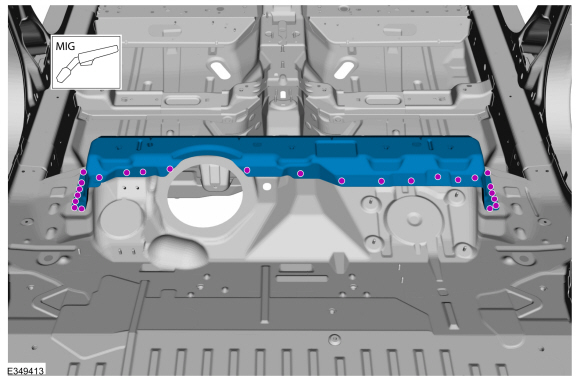

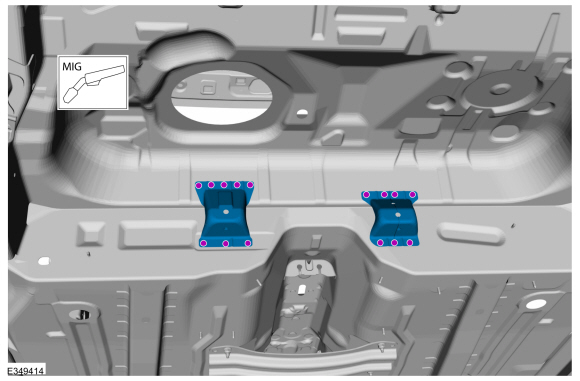

Install the welds and reinforcement.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Install the welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

install the welds and fuel tank bracket.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Dress all welds as required using typical metal finishing techniques.

-

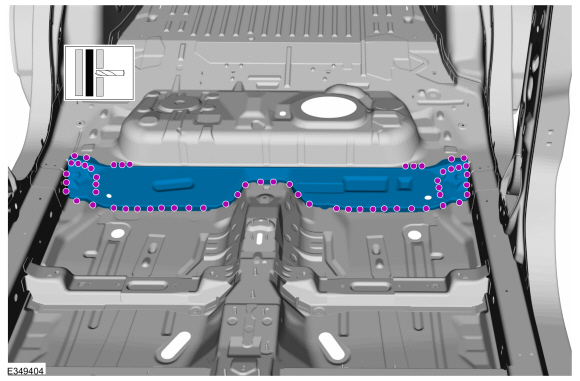

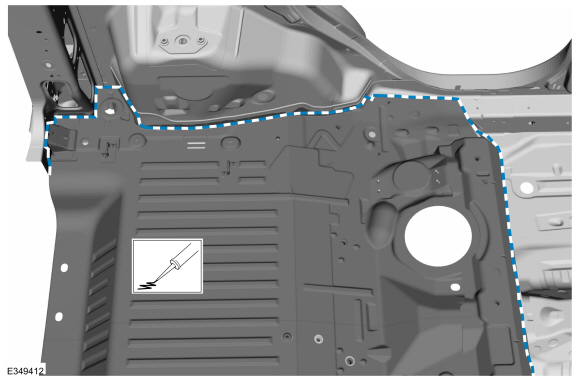

NOTE: Left hand (LH) side shown, right hand (RH) side similar.

Seam Sealing Entire Perimeter:

All seams must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

|

-

Refinish the entire repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Rear floor panel all seams must be sealed to production level.

-

install the Back Panel and Reinforcement.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Apply locally obtained butyl noise, vibration and

harshness (NVH) material in all areas noted on original panel during

removal.

-

Transfer or install new floor panel plugs.

-

Reposition the carpeting and the wiring harness to original location.

-

Install the luggage compartment trim.

-

Install the rear seat.

Refer to: Rear Seat Backrest (501-10B Rear Seats, Removal and Installation).

-

Remove the Loadspace Trim Panel.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Install the B, C and D-pillar trim panels.

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: C-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: D-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Removal and Installation - Rear Exhaust Mounting Bracket

Removal and Installation - Rear Exhaust Mounting Bracket

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds...

Removal and Installation - Rear Floor Panel Crossmember

Removal and Installation - Rear Floor Panel Crossmember

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds...

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Description and Operation - Climate Control System - Vehicles With: Electronic Manual Temperature Control (EMTC) - System Operation and Component Description

System Diagram Item Description 1 HVAC control module 2 Blower motor speed control 3 Blower motor 4 Air distribution door actuator 5 Blower motor relay 6 Air inlet door actuator 7 Temperature door actuator 8 PCM 9 Evaporator temperature sensor 10 ..

Ford Ecosport 2014-2026 Service and Repair Manual: Diagnosis and Testing - Pinpoint Test - DTC: X

U0253:00 Normal Operation and Fault Conditions The RCM uses information contained in messages from the APIM sent on the HS-CAN . DTC Fault Trigger Conditions DTC Description Fault Trigger Conditions U0253:00 Lost Communication with Accessory Protocol Interface M..