Ford Ecosport: Rear End Sheet Metal Repairs / Removal and Installation - Rear Exhaust Mounting Bracket

Special Tool(s) / General Equipment

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Removal

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Position aside the exhaust.

-

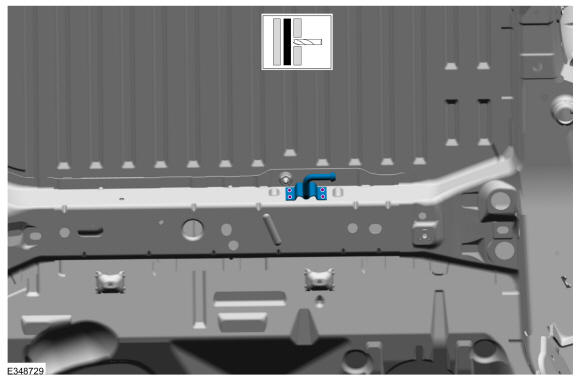

Remove the welds and the exhaust bracket.

Use the General Equipment: Spot Weld Drill Bit

|

Installation

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Drill plug weld holes in the replacement bracket.

Use the General Equipment: 8 mm Drill Bit

|

-

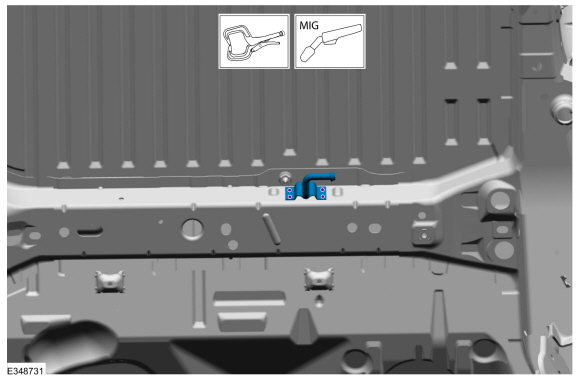

Install, properly position, clamp and weld the replacement exhaust bracket.

Use the General Equipment: Locking Pliers

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Refinish the entire repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Position and secure the exhaust in original location.

Removal and Installation - Front Floor Panel Upper Rear Crossmember

Removal and Installation - Front Floor Panel Upper Rear Crossmember

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Left hand (LH) side shown, right hand (RH) side similar...

Removal and Installation - Rear Floor Panel

Removal and Installation - Rear Floor Panel

Special Tool(s) /

General Equipment

Scraper for Straight Edges

Spherical Cutter

Hot Air Gun

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

To minimize the intrusiveness..

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Description and Operation - Electronic Engine Controls - Component Location

Item Description 1 MAF sensor 2 CMP sensor 3 CHT sensor 4 VCT oil control solenoid 5 CKP sensor 6 HO2S sensor 7 Catalyst Monitor sensor 8 ECT sensor 9 PCM Front of Engine Item Description 1 FRP sensor 2 KS..

Ford Ecosport 2014-2026 Service and Repair Manual: General Procedures - Transfer Case Draining and Filling

Materials Name Specification Motorcraft® SAE 75W-85 Premium Synthetic Hypoid Gear LubricantXY-75W85-QL WSS-M2C942-A Draining Follow the health and safety precautions. Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation). With the vehicle in NEUTRAL, position it on a hoist. ..

205-153

(T80T-4000-W)

205-153

(T80T-4000-W)

205-990

205-990