Ford Ecosport: Side Panel Sheet Metal Repairs / Removal and Installation - Rocker Panel Inner Reinforcement

Ford Ecosport 2014-2026 Service and Repair Manual / Body and Paint / Side Panel Sheet Metal Repairs / Removal and Installation - Rocker Panel Inner Reinforcement

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Grinder | |

| Belt Sander | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Removal

NOTE: The rocker panel inner reinforcement is made of DP (Dual Phase) 800 steel and cannot be sectioned. It must be removed at factory seams.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the A-pillar assembly.

Refer to: A-Pillar Assembly (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Remove the B-pillar and reinforcement.

Refer to: B-Pillar and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Remove the rocker panel outer.

Refer to: Rocker Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

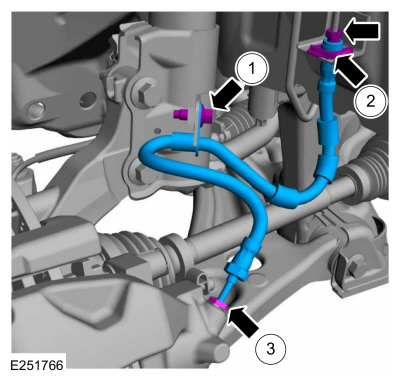

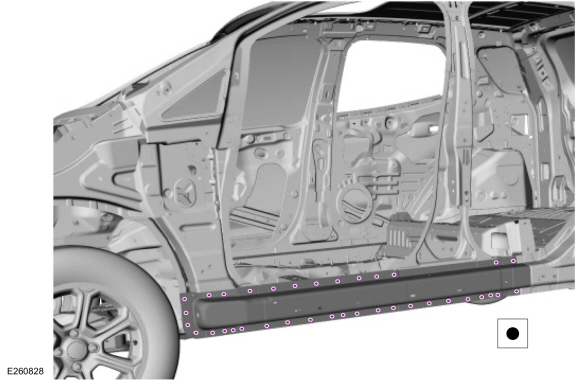

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

Use the General Equipment: Belt Sander

|

-

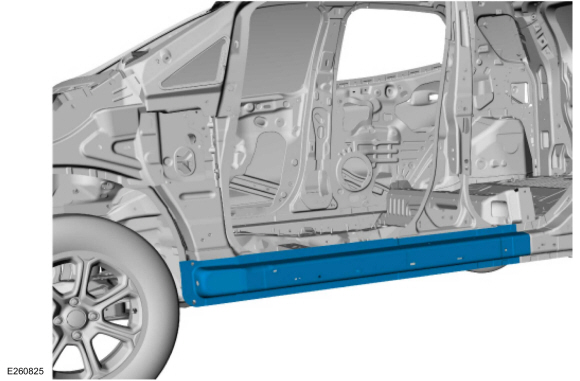

Remove the rocker panel inner reinforcement.

|

Installation

-

Repair any sheet meatal damage using typical metal finishing techniques.

-

Dress all spot weld nuggets as necessary.

Use the General Equipment: Grinder

-

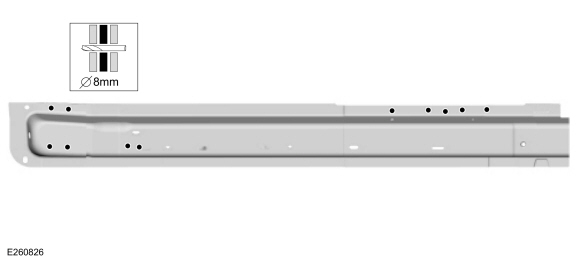

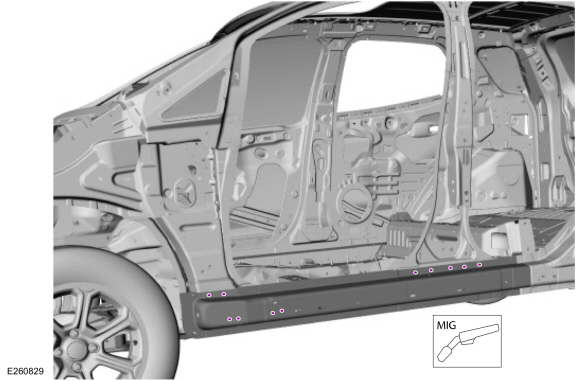

Drill plug weld holes.

Use the General Equipment: 8 mm Drill Bit

|

-

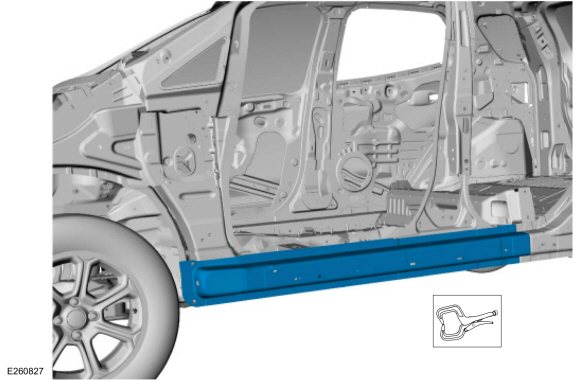

Install the reinforcement, properly position and clamp.

Use the General Equipment: Locking Pliers

|

-

NOTE: Resistance spot welds may not be placed directly over factory welds. They must be placed adjacent to the original location and match factory welds in quantity.

Install spot welds.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Install MIG plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Install the B-pillar and reinforcement.

Refer to: B-Pillar and Reinforcement (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Install the A-pillar assembly.

Refer to: A-Pillar Assembly (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Install the rocker panel outer.

Refer to: Rocker Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Removal and Installation - Rocker Panel

Removal and Installation - Rocker Panel

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Hot Air Gun

Air Body Saw

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

Remove the front door...

Removal and Installation - B-Pillar and Reinforcement

Removal and Installation - B-Pillar and Reinforcement

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spherical Cutter

Hot Air Gun

Air Body Saw

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTICE:

Protect the vehicle interior from damage during repair process...

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Removal and Installation - Spring

Special Tool(s) / General Equipment Spring Compressor Vise Removal NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense...

Ford Ecosport 2014-2026 Service and Repair Manual: Removal and Installation - Front Wheel Speed Sensor

Removal NOTE: Removal steps in this procedure may contain installation details. NOTE: Note the position of the front wheel speed sensor before removal. Remove the wheel and tire. Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation)...

Copyright © 2026 www.foecosport2.com