Ford Ecosport: Roof Sheet Metal Repairs / Removal and Installation - Roof Rear Frame

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

Depower the SRS .

Refer to: Supplemental Restraint System (SRS) Depowering (501-20B Supplemental Restraint System, General Procedures).

-

If required:

Dimensionally restore the vehicle to pre-damaged condition.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

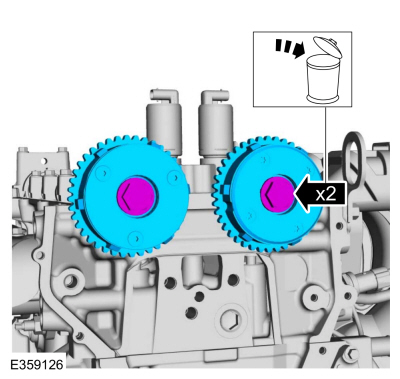

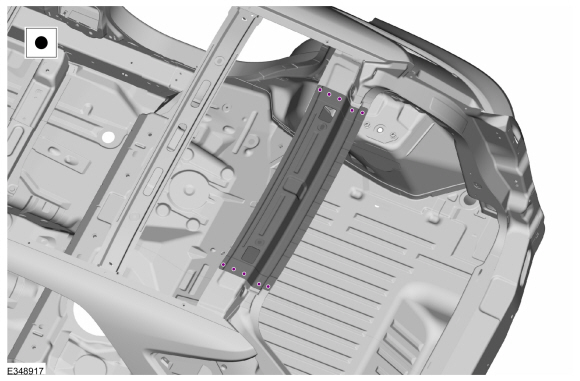

Remove the welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

NOTE: Pay particular attention to the location of adhesives and sealers to aid in installation.

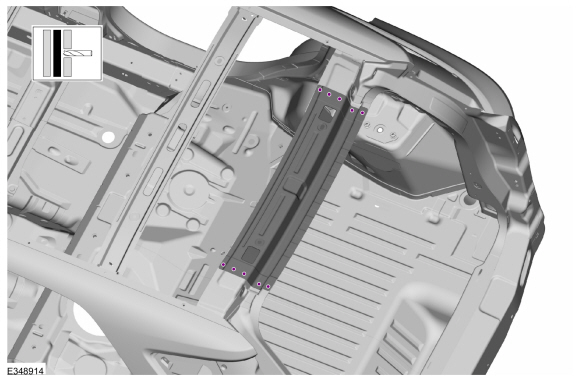

Remove the roof rear frame.

|

Installation

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

-

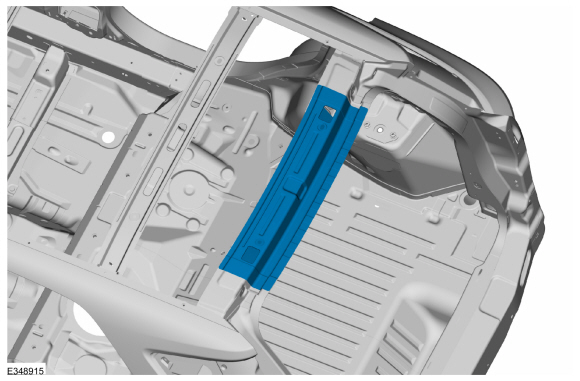

Install, properly position and clamp the roof rear frame.

Use the General Equipment: Locking Pliers

|

-

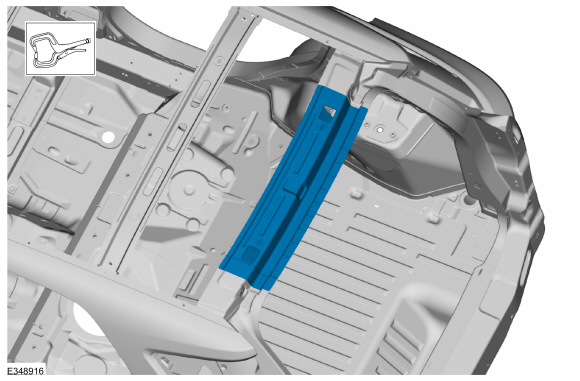

Install the welds.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Metal finish as required using typical metal finishing techniques.

-

Sealing work:

All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the roof panel.

Refer to: Roof Panel (501-28 Roof Sheet Metal Repairs, Removal and Installation).

-

Repower the SRS .

Refer to: Supplemental Restraint System (SRS) Repowering (501-20B Supplemental Restraint System, General Procedures).

Removal and Installation - Roof Reinforcement

Removal and Installation - Roof Reinforcement

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Factory welds may be substituted with resistance or metal

inert gas (MIG) plug welds...

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Diagnosis and Testing - Pinpoint Test - DTC: T, Vehicles With: Rear Seat Side Airbag

B1202:11, B1202:12 and B1202:13 Refer to Wiring Diagrams Cell 46 for schematic and connector information. Normal Operation and Fault Conditions The RCM briefly activates the PAD indicator to prove-out and verify correct functional operation of the PAD indicator to the occupants...

Ford Ecosport 2014-2026 Service and Repair Manual: Description and Operation - Power Steering - System Operation and Component Description

System Operation System Diagram Item Description 1 EPAS column 2 HS-CAN 3 EPAS motor 4 Steering shaft position sensor 5 Steering shaft torque sensor 6 PSCM 7 IPC 8 ABS module 9 PCM Network Message Chart ..