Ford Ecosport: Rear End Sheet Metal Repairs / Removal and Installation - Rear Lamp Mounting Panel

Ford Ecosport 2014-2026 Service and Repair Manual / Body and Paint / Rear End Sheet Metal Repairs / Removal and Installation - Rear Lamp Mounting Panel

Special Tool(s) / General Equipment

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

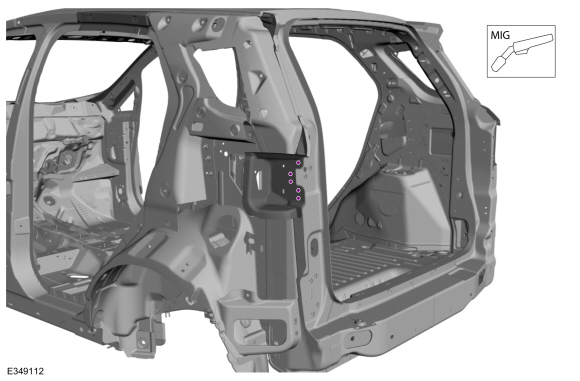

NOTE: Factory welds may be substituted with resistance or metal inert gas (MIG) plug welds. Resistance welds may not be placed directly over original location. They must be placed adjacent to original location and match factory welds in quantity. Metal inert gas (MIG) plug welds must equal factory welds in both location and quantity.

NOTE: Adequately protect all adjacent areas against cutting, grinding and welding procedures.

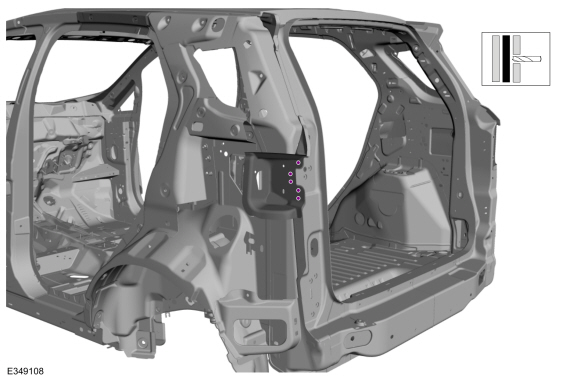

NOTE: LH side shown, RH side similar.

-

Remove the Quarter Panel LH.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

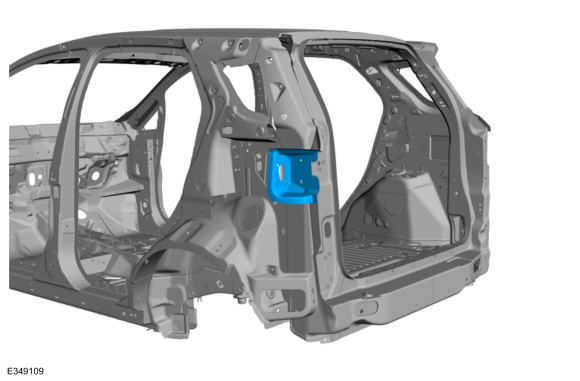

Remove the rear lamp mounting panel.

|

Installation

NOTE: LH side shown, RH side similar.

-

Refer to: Joining Techniques (501-25 Body Repairs - General Information, General Procedures).

-

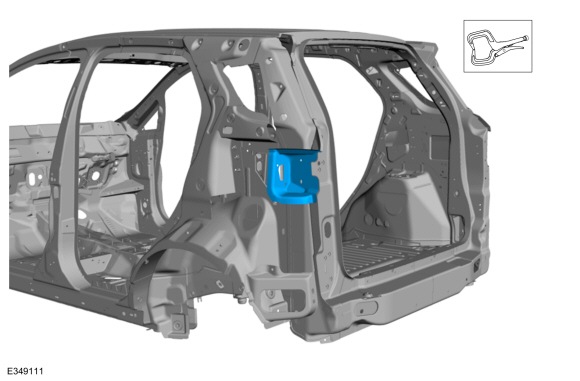

Drill holes in the replacement panel for plug welding.

Use the General Equipment: 8 mm Drill Bit

|

-

Install, properly position and clamp the rear lamp mounting panel.

Use the General Equipment: Locking Pliers

|

-

Install plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Finish repair area using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the Quarter Panel LH.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Removal and Installation - Rear Side Member

Removal and Installation - Rear Side Member

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTE:

Rear doors removed for clarity...

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Description and Operation - Safety Precautions - Overview

Overview Before beginning any service procedure in this manual, refer to health and safety warnings in section 100-00 General Information. Failure to follow this instruction may result in serious personal injury. WARNING: Before servicing any tire, ask the customer if anyone injected a tire sealant into the tire...

Ford Ecosport 2014-2026 Service and Repair Manual: Removal and Installation - Crankshaft Pulley

Special Tool(s) / General Equipment 303-1521Alignment Tool, Crankshaft Position SensorTKIT-2010C-FLM 303-1686Holding Tool, Camshaft 303-1689Holding Tool, Crank Damper 303-507Timing Peg, Crankshaft TDCTKIT-2001N-FLMTKIT-2001N-ROW Trolley Jack Wooden Block Removal NOTICE: Do not loosen or remove the crankshaft pulley bo..

Copyright © 2026 www.foecosport2.com

WARNING:

Wear eye and ear protection when servicing a vehicle.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Wear eye and ear protection when servicing a vehicle.

Failure to follow this instruction may result in serious personal

injury.