Ford Ecosport: Automatic Transmission - 6-Speed Automatic Transmission – 6F35 / Overhaul - Main Control Valve Body

Special Tool(s) /

General Equipment

|

307-636

Alignment Pins- Valve Body

TKIT-2008ET-FLM

TKIT-2008ET-ROW |

| Flat Headed Screw Driver |

| Magnetic Socket |

| Long Nose Pliers |

Main Control Valve Body and Solenoid Body

-

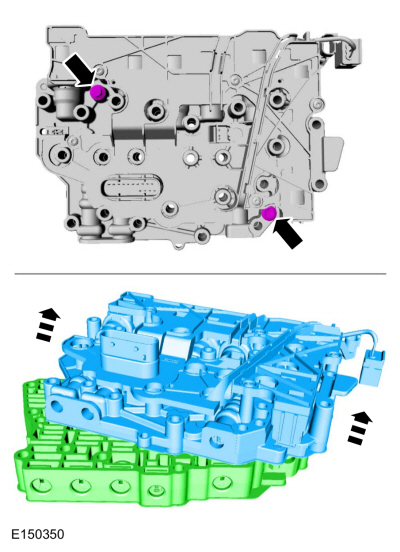

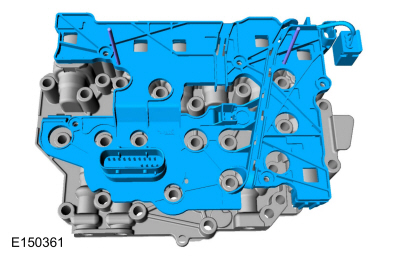

Remove the solenoid body-to-valve body bolts and separate the solenoid body from the valve body.

-

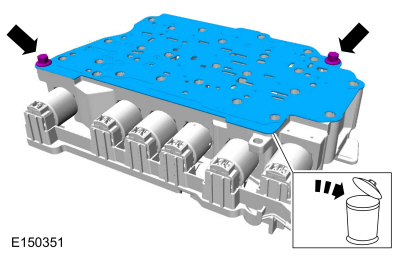

Remove the separator plate-to-solenoid body bolts and remove and discard the separator plate.

Main Control Valve Body

-

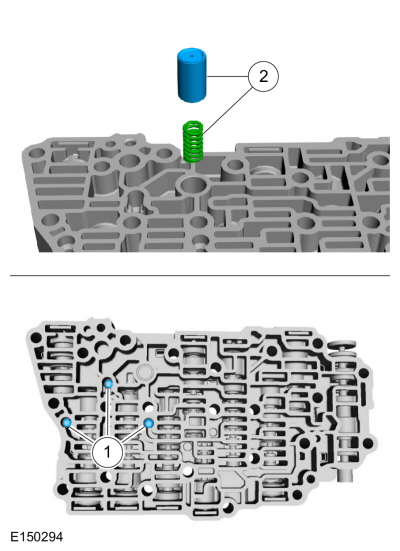

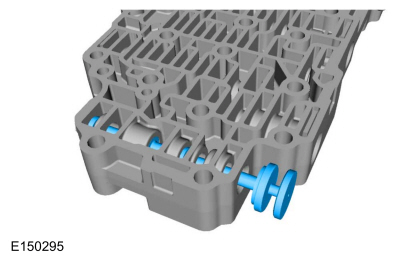

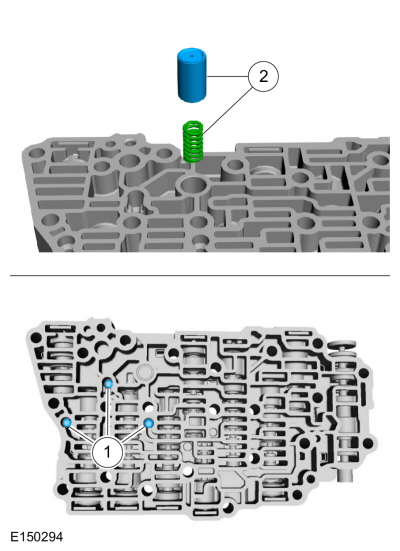

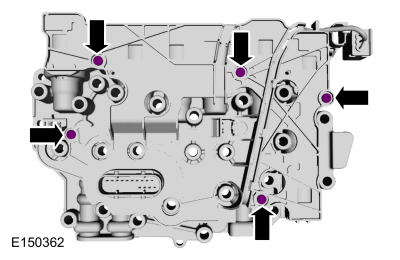

Remove the check balls, solenoid damper and the spring.

-

Check balls

-

Solenoid damper and spring

-

Remove the manual valve.

|

|

-

NOTICE:

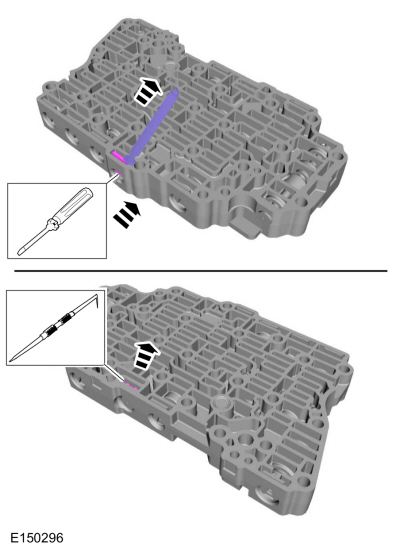

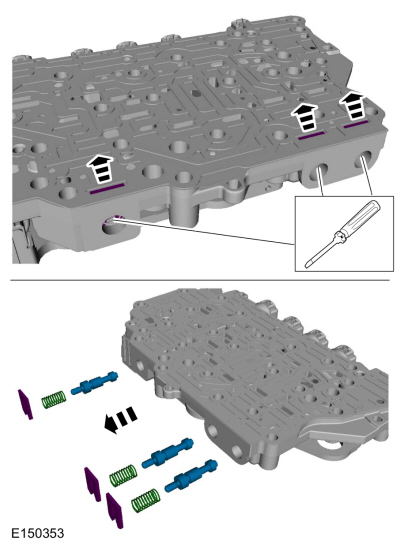

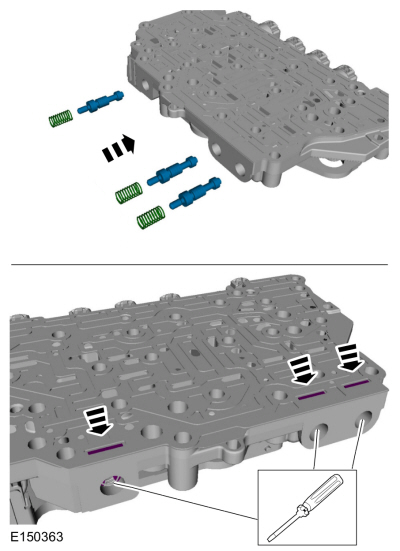

Remove the valves by tapping the valve body on the

palm of the hand to slide the valves out of the bores or by threading a

4-mm bolt into the valves and pulling them out. If it is necessary to

use a pick, use extreme caution to prevent damaging the valves or valve

bores. If necessary, disassemble parts of the main control valve body in

small groups. Arrange the parts as they are removed to avoid mixing

similar pieces.

NOTE:

The bypass valve is held in with a spring-loaded

retainer. Be careful not to lose the retainer when removing it.

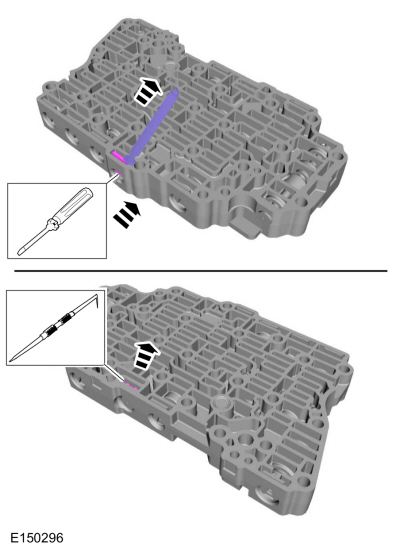

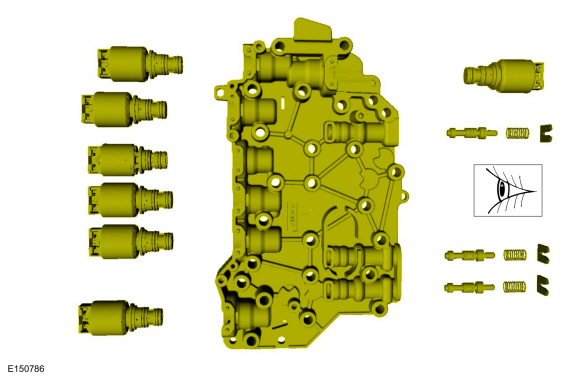

Compress the valve springs with a screwdriver and remove

the retainers with a magnet. Use a pick to remove the bypass valve

retainer. Remove the individual valves and springs from the main control

valve body by tapping the valve body on the palm of the hand to slide

the valves out of the bores. If needed, use a 4-mm bolt to thread into

the valves to remove the valves.

Use the General Equipment: Flat Headed Screw Driver

Use the General Equipment: Magnetic Socket

|

|

-

NOTICE:

Do not stone or polish any valves or damage to the

valves can occur. If the valves do not move freely, install a new

assembly.

Clean the valves, springs and main control valve body.

-

NOTICE:

Do not stone or polish any valves or damage to the

valves can occur. If the valves do not move freely, install a new

assembly.

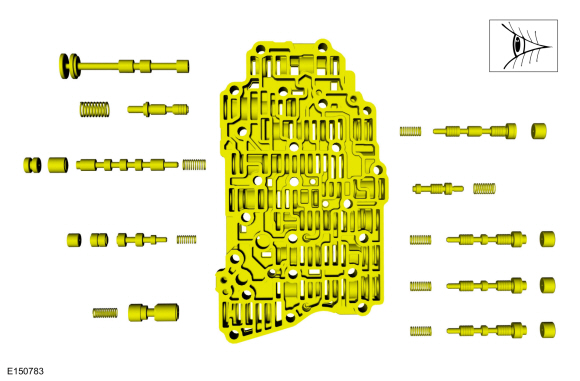

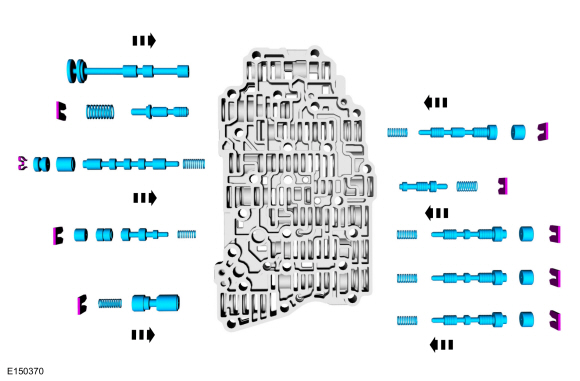

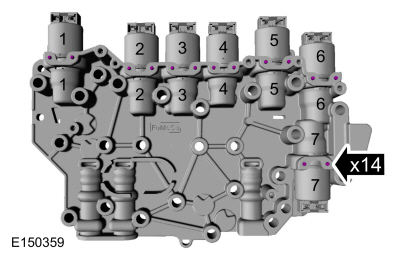

Install the valve body valves, springs and retaining

clips in the main control valve body. For valve and spring locations

Refer to: Main Control Valve Body (307-01B Automatic Transmission -

6-Speed Automatic Transmission – 6F35, Description and Operation).

-

Install the manual valve in the valve body.

-

Install the check balls, spring and the solenoid damper.

-

Check balls

-

Solenoid damper and spring

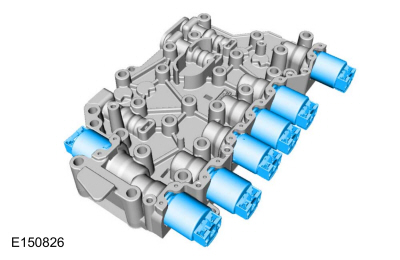

Solenoid Body

-

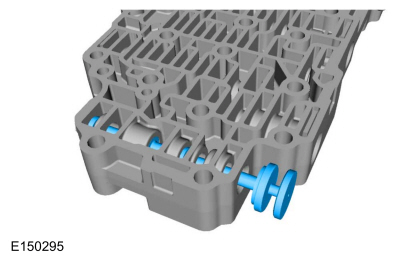

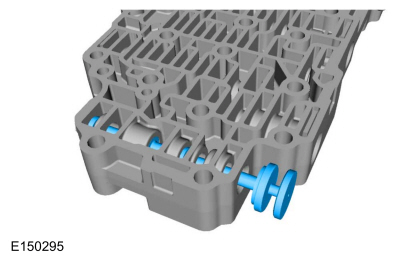

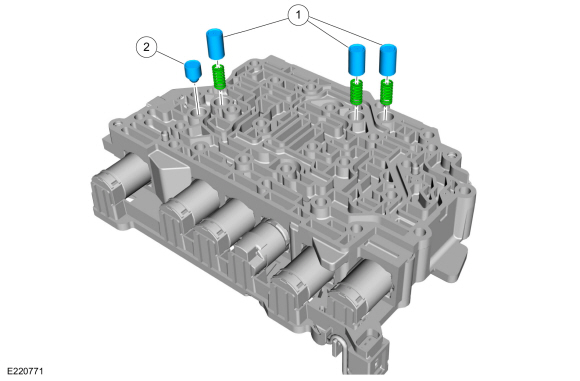

Remove the solenoid body dampers and springs.

-

Damper pistons and springs

-

Elastomeric damper

-

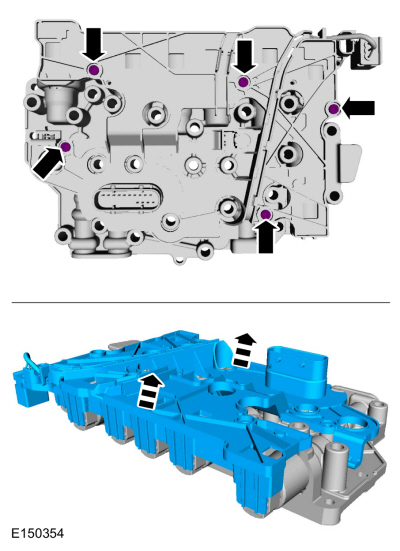

Compress the valve springs and remove the retainers with

a magnet. Remove the individual valves and springs from the solenoid

body by tapping it on the palm of the hand to slide the valves out of

the bores.

Use the General Equipment: Flat Headed Screw Driver

Use the General Equipment: Magnetic Socket

-

NOTICE:

Be careful not to bend or twist the transmission

internal wiring harness frame or solenoid terminals when removing the

transmission internal wiring harness frame or damage can occur.

Remove the screws and carefully remove the transmission

internal wiring harness frame from the solenoids by lifting it straight

up evenly.

-

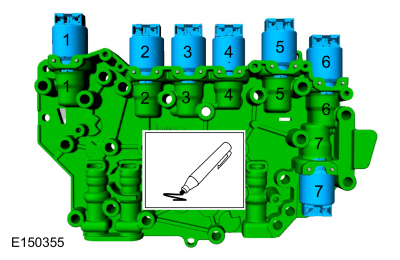

NOTICE:

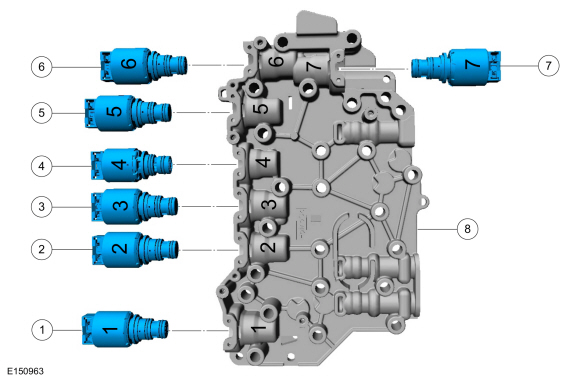

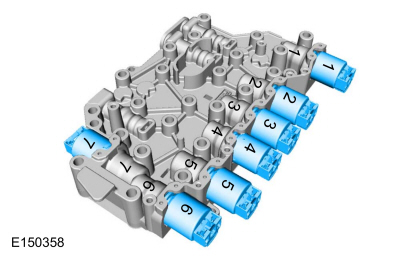

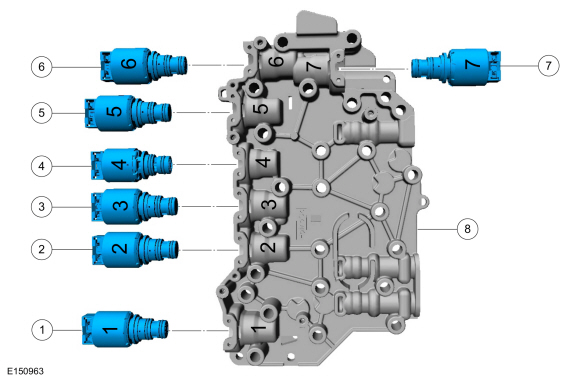

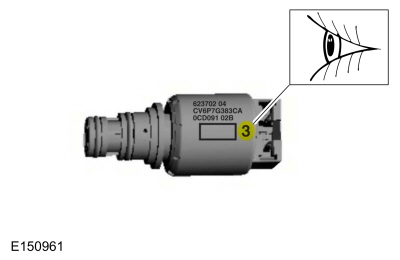

The solenoids are calibrated from the factory and

are not all the same. Failure to mark the solenoids to the ports they

were originally in can result in mixing the solenoids and cause damage

to the transmission or a harsh shift.

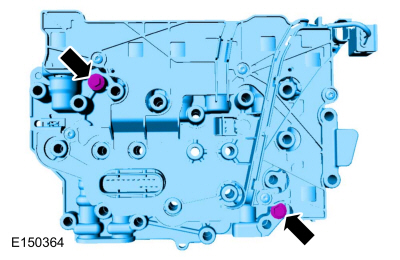

Using a paint marker, number the solenoids and the

solenoid body to correspond with the ports from which the solenoids are

located in the solenoid body

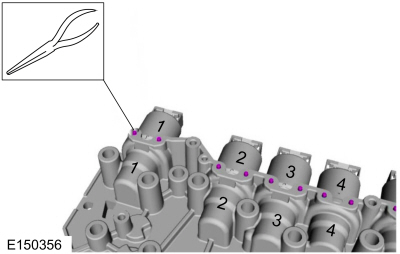

-

Remove the solenoid retaining pins.

Use the General Equipment: Long Nose Pliers

-

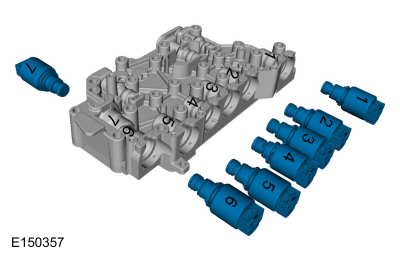

Remove the solenoids from the solenoid body.

-

NOTICE:

Be careful not to wash the numbers from the

solenoids or the solenoid body. Failure to install the solenoids in the

ports they were originally in can result in damage to the transmission

or a harsh shift.

NOTICE:

Do not stone or polish any valves or damage to the

valves can occur. If the valves do not move freely during assembly,

install a new solenoid body.

Clean and inspect the solenoid body, solenoids and valve assemblies for damage.

-

Inspect the solenoid screens for debris that may restrict fluid flow through the screen.

-

NOTICE:

The solenoids are calibrated from the factory and

are not all the same. Failure to install the solenoids in the ports they

were originally in can result in damage to the transmission or a harsh

shift.

If new solenoid(s) are not being installed, position the solenoids in their corresponding solenoid body ports.

-

NOTE:

If installing a new Variable Force Solenoid (VFS), determine the base

part number of the solenoid(s). The TCC solenoid, SSA and SSC are all

normally low pressure solenoids. The LPC solenoid, SSB and SSD are all

normally high pressure solenoids. SSE is not a Variable Force Solenoid

(VFS); it is an ON/OFF solenoid.

-

LPC solenoid (normally high) part number 7G383

-

SSC (normally low) part number 7G136

-

TCC solenoid (normally low) part number 7G136

-

SSE (normally closed [OFF]) part number 7G484

-

SSA (normally low) part number 7G136

-

SSB (normally high) part number 7G383

-

SSD (normally high) part number 7G383

-

Solenoid body part number 7G391

|

|

-

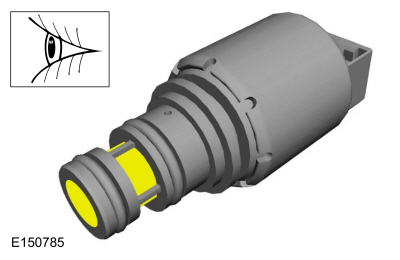

If installing new solenoids, note the color of the

plastic nozzle and the large O-ring. High pressure solenoids, such as

the LPC solenoid, SSB and SSD , have black plastic nozzles and orange

O-rings. Low pressure solenoids, such as the TCC solenoid, SSA and SSC ,

have brown plastic nozzles and green O-rings. The solenoids can only be

replaced with the same color solenoid.

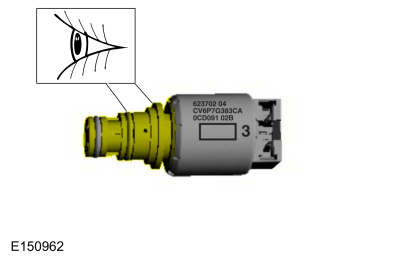

-

Determine the part number suffix by checking the

solenoid service band number etched on the side of the solenoid. The

band number is next to the two-dimensional matrix barcode on the side of

the solenoid and will be a 1, 2, 3, 4 or 5. Determine the part number

suffix and match the new solenoid base part number and suffix with the

old solenoid.

-

= (B)

-

= (C)

-

= (D)

-

= (E)

-

= (F)

-

Install the solenoid(s) in the solenoid body.

-

Install the solenoid retaining pin(s).

-

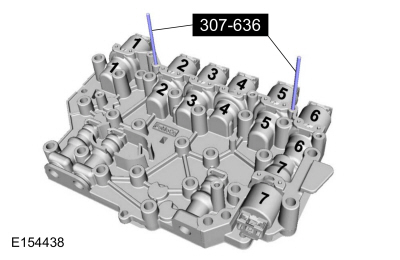

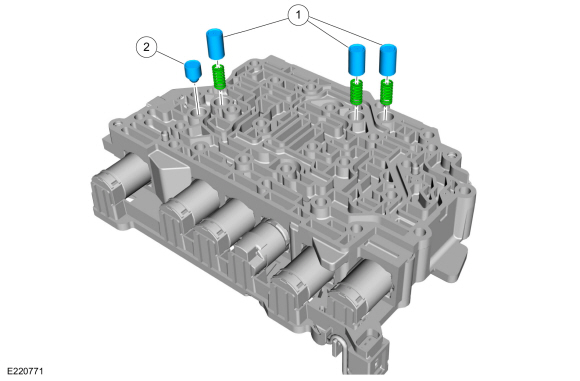

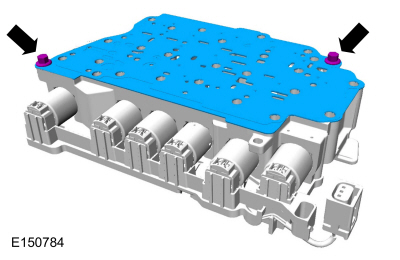

Install the special tools in the solenoid body to align

the transmission internal wiring harness frame for installation.

Use Special Service Tool: 307-636

Alignment Pins- Valve Body.

-

NOTICE:

Be careful not to bend or twist the transmission

internal wiring harness frame or solenoid terminals when removing the

transmission internal wiring harness frame or damage can occur.

Position the transmission internal wiring harness frame

on the guide pins and carefully install the transmission internal wiring

harness frame by pushing it straight down into the solenoids.

-

Install the transmission internal wiring harness frame screws.

Torque:

31 lb.in (3.5 Nm)

-

NOTICE:

If the valves do not move freely during assembly,

install a new solenoid body. Failure to install a new solenoid body can

result in a harsh shift or damage to the transmission.

Install the solenoid body valves, springs and retaining

clips in the solenoid body. For valve and spring locations

Refer to: Main Control Valve Body (307-01B Automatic Transmission -

6-Speed Automatic Transmission – 6F35, Description and Operation).

Use the General Equipment: Flat Headed Screw Driver

-

Install the solenoid body dampers and springs.

-

Damper pistons and springs

-

Elastomeric damper

Main Control Valve Body and Solenoid Body

-

Install the new separator plate and the separator plate-to-solenoid body bolts.

Torque:

89 lb.in (10 Nm)

-

Position the solenoid body assembly on the valve body and install the solenoid body-to-valve body bolts.

Torque:

89 lb.in (10 Nm)

Removal

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation)...

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge

205-153

(T80T-4000-W)

Handle

205-990Installer, Axle SealTKIT-2012A-FLTKIT-2012A-ROW

211-061

(T78P-3504-N1)

Remover, Roll Pin

303-D011

(D80L-100-G)

Actuator Pin (Dia 3/16)

..

Other information:

Special Tool(s)

Alignment Pins, Subframe205-870

Adapter for 205-870205-870-01

Inspection and Verification

Verify the customer concern.

Visually inspect for obvious signs of mechanical damage.

Visual Inspection Chart

Mechanical

Tire pressure(s)

..

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the active grill shutter.

Refer to: Active Grille Shutter - 2.0L Duratec-HE (125kW/170PS) – MI4 (501-02 Front End Body Panels, Removal and Installation).

Refer to: Active Grille Shutter - 1.0L EcoBoost (92kW/125PS) (501-02 Front End Body Panels, Removal and Installation).

..

Removal and Installation - Turbine Shaft Speed (TSS) Sensor

Removal and Installation - Turbine Shaft Speed (TSS) Sensor Overhaul - Transmission

Overhaul - Transmission