Ford Ecosport: Engine System - General Information / General Procedures - Crankshaft Main Bearing Journal Clearance

Ford Ecosport 2014-2026 Service and Repair Manual / Engine / Engine System - General Information / General Procedures - Crankshaft Main Bearing Journal Clearance

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

NOTE: Crankshaft main bearing journals must be within specifications before checking journal clearance.

Remove the crankshaft main bearing cap and crankshaft main bearing.

-

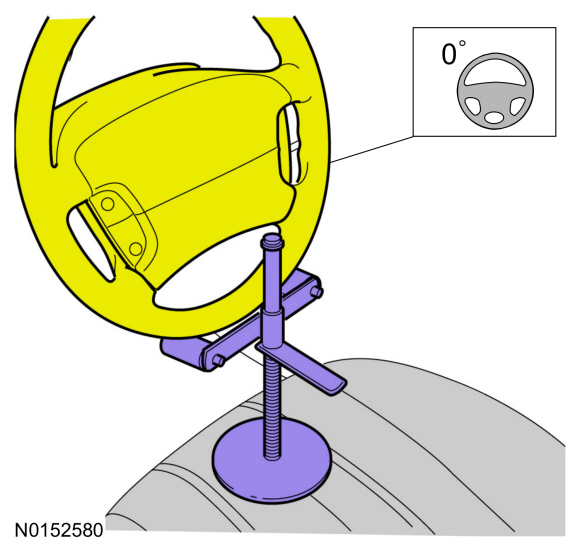

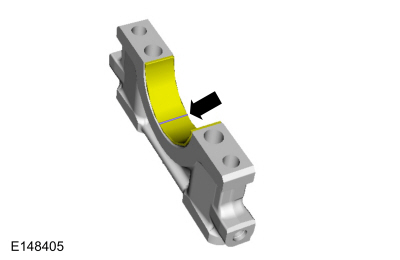

Position a piece of Plastigage across the crankshaft main bearing surface.

|

-

NOTE: Do not turn the crankshaft while carrying out this procedure.

Install and tighten to specifications, then remove the crankshaft main bearing cap.

-

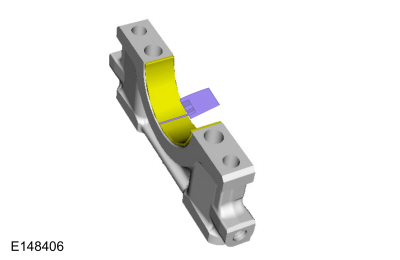

Measure the Plastigage to get the crankshaft main

bearing clearance. The Plastigage should be smooth and flat. A changing

width indicates a tapered or damaged crankshaft or crankshaft bearing.

|

General Procedures - Connecting Rod Bearing Journal Clearance

General Procedures - Connecting Rod Bearing Journal Clearance

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

NOTE:

The crankshaft connecting rod journals must be

within specifications to check the connecting rod bearing journal

clearance...

General Procedures - Cylinder Block Core Plug Replacement

General Procedures - Cylinder Block Core Plug Replacement

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

Materials

Name

Specification

Motorcraft® Threadlock 262TA-26

WSK-M2G351-A6

Repair

All core plugs

NOTE:

Cylinder block core plug shown, cylinder head core plug similar...

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Description and Operation - Airbag and Seatbelt Pretensioner Supplemental Restraint System (SRS) - Vehicles With: Rear Seat Side Airbag - Component Location

Item Description 1 LH and RH front impact severity sensors 2 BECMB 3 Passenger front door side impact sensor 4 OCSM (includes OCS sensor and gel-filled bladder) 5 PAD indicator 6 RCM 7 Front passenger seatbelt buckle (includes buckle sensor) 8 Driver and passenger..

Ford Ecosport 2014-2026 Service and Repair Manual: Description and Operation - Noise, Vibration and Harshness

Sound Deadeners and Insulators NOTICE: Mastic is made of a combustible material and should be removed prior to carrying out welding procedures to the area. Heat zones from welding near mastic may cause the mastic material to burn. NOTICE: Corrosion protection must be restored to the area after the mastic material is applied. Corrosion protection products may be wax based a..

Copyright © 2026 www.foecosport2.com