Ford Ecosport: Engine System - General Information / General Procedures - Connecting Rod Bearing Journal Clearance

Ford Ecosport 2014-2026 Service and Repair Manual / Engine / Engine System - General Information / General Procedures - Connecting Rod Bearing Journal Clearance

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

NOTE: The crankshaft connecting rod journals must be within specifications to check the connecting rod bearing journal clearance.

Remove the connecting rod bearing cap and connecting rod bearing.

-

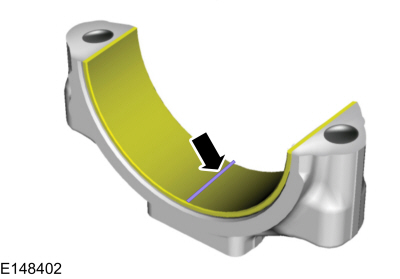

Position a piece of Plastigage across the bearing surface.

|

-

NOTE: Do not turn the crankshaft during this step.

Install and tighten to specifications, then remove the connecting rod bearing cap.

-

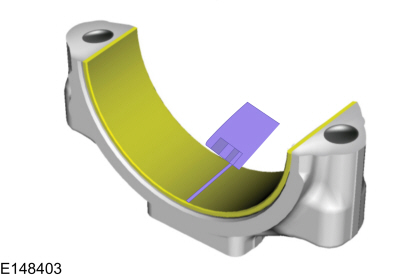

Measure the Plastigage to get the connecting rod bearing

journal clearance. The Plastigage should be smooth and flat. A changing

width indicates a tapered or damaged connecting rod or connecting rod

bearing.

|

General Procedures - Compression and Cylinder Leakage Test

General Procedures - Compression and Cylinder Leakage Test

Make sure the oil in the crankcase is of the correct

viscosity and at the correct level and that the battery is correctly

charged. Operate the vehicle until the engine is at normal operating

temperature...

General Procedures - Crankshaft Main Bearing Journal Clearance

General Procedures - Crankshaft Main Bearing Journal Clearance

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

NOTE:

Crankshaft main bearing journals must be within specifications before checking journal clearance...

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Diagnosis and Testing - Daytime Running Lamps (DRL)

DTC Chart: BCM Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). BCM DTC Chart DTC Description Action B124A:11 Right Daytime ..

Ford Ecosport 2014-2026 Service and Repair Manual: Diagnosis and Testing - Brake System

Symptom Chart(s) Symptom Chart: Brake System Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). Condition Possible Sources Actions The red brake warning indicator and the y..

Copyright © 2026 www.foecosport2.com

205-153

(T80T-4000-W)

205-153

(T80T-4000-W)

205-990

205-990