Ford Ecosport: Engine - 2.0L Duratec-HE (129kW/175PS) / General Procedures - Valve Clearance Adjustment

Ford Ecosport 2014-2026 Service and Repair Manual / Engine / Engine - 2.0L Duratec-HE (129kW/175PS) / General Procedures - Valve Clearance Adjustment

Special Tool(s) / General Equipment

| Feeler Gauge |

Check

-

Remove the valve cover.

Refer to: Valve Cover (303-01C Engine - 2.0L Duratec-HE (129kW/175PS), Removal and Installation).

-

Remove the RH front wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

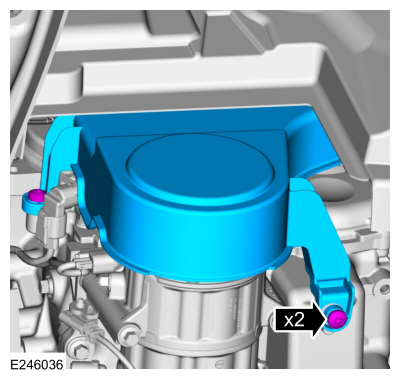

Remove the fasteners and the accessory drive belt cover.

|

-

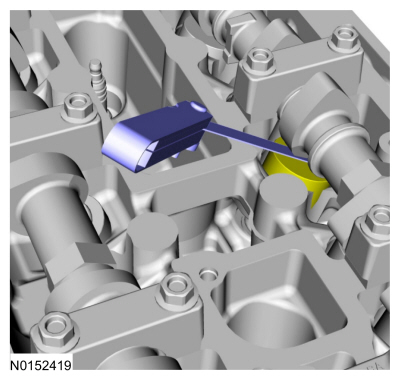

NOTE: Turn the engine clockwise only, and only use the crankshaft bolt.

NOTE: Measure the clearance of each valve at base circle, with the lobe pointed away from the tappet.

Use a feeler gauge to measure the clearance of each valve and record its location.

Use the General Equipment: Feeler Gauge

|

-

NOTE: The number on the valve tappet only reflects the digits that follow the decimal. For example, a tappet with the number 0.650 has the thickness of 3.650 mm.

NOTE: Select tappets using this formula: tappet thickness = measured clearance + the existing tappet thickness - nominal clearance.

NOTE: The nominal clearance is:

- intake: 0.25 mm (0.0095 in).

- exhaust: 0.36 mm (0.0142 in).

NOTE: The acceptable clearances after being fully installed are:

- intake: 0.19-0.31 mm (0.007-0.012 in).

- exhaust: 0.30-0.42 mm (0.012-0.017 in).

-

If any tappets do not measure within specifications, install new tappets in those locations.

Adjustment

-

NOTE: The following step is only necessary if adjustment is required.

Remove the camshafts.

Refer to: Camshaft (303-01C Engine - 2.0L Duratec-HE (129kW/175PS), Removal and Installation).

Removal and Installation - Camshaft

Removal and Installation - Camshaft

Special Tool(s) /

General Equipment

303-1565Alignment Tool, CamshaftTKIT-2010C-FLM

303-507Timing Peg, Crankshaft TDCTKIT-2001N-FLMTKIT-2001N-ROW

Feeler Gauge

Materials

Name

Specification

Flange SealantCU7Z-19B508-A

WSS-M2G348-A11

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important..

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Removal and Installation - Steering Column Multifunction Switch RH

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the steering column shrouds. Refer to: Steering Column Shrouds (501-05 Interior Trim and Ornamentation, Removal and Installation). NOTE: Make sure that the component terminals are not bent or damaged. Remove the RH steering column multifunction switch. ..

Ford Ecosport 2014-2026 Service and Repair Manual: Removal and Installation - Crankshaft Pulley

Special Tool(s) / General Equipment 303-1521Alignment Tool, Crankshaft Position SensorTKIT-2010C-FLM 303-1686Holding Tool, Camshaft 303-1689Holding Tool, Crank Damper 303-507Timing Peg, Crankshaft TDCTKIT-2001N-FLMTKIT-2001N-ROW Trolley Jack Wooden Block Removal NOTICE: Do not loosen or remove the crankshaft pulley bo..

Copyright © 2026 www.foecosport2.com

WARNING:

Wear eye and ear protection when servicing a vehicle.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Wear eye and ear protection when servicing a vehicle.

Failure to follow this instruction may result in serious personal

injury.