Ford Ecosport: Engine System - General Information / General Procedures - Cylinder Head Distortion

Ford Ecosport 2014-2026 Service and Repair Manual / Engine / Engine System - General Information / General Procedures - Cylinder Head Distortion

Special Tool(s) / General Equipment

| Feeler Gauge |

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

NOTE: Make sure all cylinder head surfaces are clear of any gasket material, silicone sealant, oil and coolant. The cylinder head surface must be clean and dry before running a flatness check.

NOTE: Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent. For example, if the Straightedge is 61 cm (24 in) long, the machined edge must be flat within 0.010 mm (0.0004 in) from end to end.

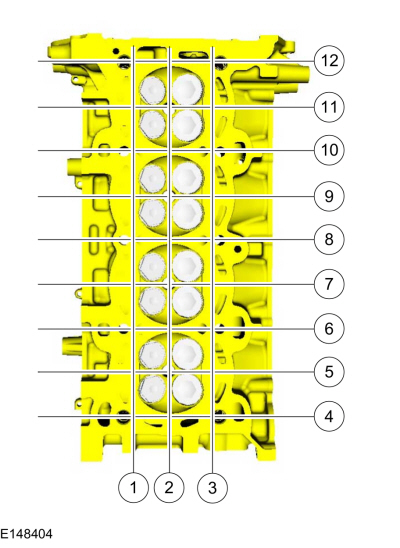

Using a Straightedge and a Feeler Gauge Set, inspect the cylinder head for flatness in the sequence shown.

Use the General Equipment: Feeler Gauge

|

General Procedures - Cylinder Bore Taper

General Procedures - Cylinder Bore Taper

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the cylinder bore at the top, middle and bottom

of piston ring travel in 2 directions as indicated...

General Procedures - Engine Noise Identification and Location

General Procedures - Engine Noise Identification and Location

NOTE:

This procedure uses multiple tools/methods to help locate the

source of engine noise. It may be necessary to repeatedly compare the

sound between the tools/methods to help locate the source of the noise...

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Removal and Installation - Tire Pressure Monitoring System (TPMS) Sensor

Removal WARNING: The Tire Pressure Monitoring System (TPMS) sensor battery may release hazardous chemicals if exposed to extreme mechanical damage. If these chemicals contact the skin or eyes, flush immediately with water for a minimum of 15 minutes and get prompt medical attention...

Ford Ecosport 2014-2026 Service and Repair Manual: Diagnosis and Testing - Transmission Stall Speed Test

Stall Speed Test WARNING: Block all wheels, set the parking brake and firmly apply the service brake to reduce the risk of vehicle movement during this procedure. Failure to follow these instructions may result in serious personal injury...

Copyright © 2026 www.foecosport2.com

WARNING:

Wear eye and ear protection when servicing a vehicle.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Wear eye and ear protection when servicing a vehicle.

Failure to follow this instruction may result in serious personal

injury.