Ford Ecosport: Engine System - General Information / General Procedures - Exhaust Manifold Cleaning and Inspection

Ford Ecosport 2014-2026 Service and Repair Manual / Engine / Engine System - General Information / General Procedures - Exhaust Manifold Cleaning and Inspection

Special Tool(s) / General Equipment

| Feeler Gauge |

Cleaning

-

Clean the exhaust manifold using a suitable solvent. Use

a plastic scraping tool to clean the gasket sealing surfaces.

Inspection

-

NOTE: New exhaust manifold gaskets, studs, nuts and/or bolts must be installed when an exhaust manifold is serviced.

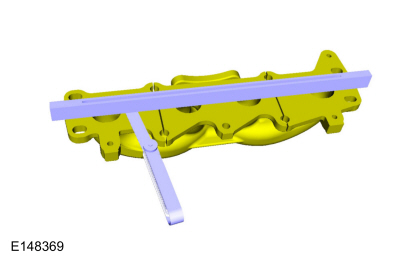

NOTE: Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent. For example, if the Straightedge is 61 cm (24 in) long, the machined edge must be flat within 0.010 mm (0.0004 in) from end to end.

Using the Straightedge and a Feeler Gauge Set, check the exhaust manifold sealing surface for warpage. If the warpage is greater than 0.76 mm (0.0299 in), install a new exhaust manifold.

Use the General Equipment: Feeler Gauge

|

General Procedures - Engine Noise Identification and Location

General Procedures - Engine Noise Identification and Location

NOTE:

This procedure uses multiple tools/methods to help locate the

source of engine noise. It may be necessary to repeatedly compare the

sound between the tools/methods to help locate the source of the noise...

General Procedures - Intake Manifold Vacuum Test

General Procedures - Intake Manifold Vacuum Test

Bring the engine to normal operating temperature. Connect

the Vacuum/Pressure Tester to the intake manifold. Run the engine at the

specified idle speed...

Other information:

Ford Ecosport 2014-2026 Service and Repair Manual: Description and Operation - Gasoline and Gasoline-Ethanol Fuel Systems Health and Safety Precautions

WARNING: Before working on or disconnecting any of the fuel tubes or fuel system components, relieve the fuel system pressure to prevent accidental spraying of fuel. Fuel in the fuel system remains under high pressure, even when the engine is not running...

Ford Ecosport 2014-2026 Service and Repair Manual: Diagnosis and Testing - Steering Wheel and Column Electrical Components

DTC Charts Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. REFER to: Diagnostic Methods (100-00 General Information, Description and Operation). BCM DTC Chart DTC Description Action B1026:04 Steering Column Lock: ..

Copyright © 2026 www.foecosport2.com